R 1 2698 mm 1062 in r 2 3175 mm 125 in h 0254 μm total surface roughness 10 μin ΔP 18 MPa 265 psi η 10 x 10 3 Pas 145 x 10 7 lbf-secin 2 See Equation 1 for how the theoretical leakage rate of a liquid. With the seal face rotating in clockwise direction rotating in clockwise direction L anti clockwise Looking from the stationary seat toward the seal face Looking from the drive side with the shaft with the seal face rotating in anticlockwise direction rotating in anticlockwise direction S independent of direction of rotation.

Energies Free Full Text Multifield Coupling Model And Performance Analysis Of A Hydrostatic Mechanical Seal Html

1 Mechanical Seal should not seize during start up and operation due to contact with product.

. 12 Design An essential mechanical seal contains three sealing points. Assume that mass leakage approaches zero. This concept is also shown in Figure 2 where k 0 for line contact at the seal outside diameter and k 1 for line contact at the inside diameter when the pressure to be sealed is.

The stationary part of the seal is fitted to the pump housing with a static seal this may be sealed with an o-ring or gasket clamped between the stationary portion and the pump housing. Craig 3 Introduction Precision machines are essential elements of an industrial society. An o-ring is a type of mechanical seal which fills the space between two or more mating surfaces generally to prevent leakage from or into the joined objects while under compression.

Mechanical seals are designed to overcome these drawbacks. 2 Ease in fabrication and material machining. Mechanical seals classified by Design.

Mechanical Design Fundamentals K. One must identify the application data or operating conditions to properly select the type of seal and materials of construction to ensure maximum performance from the seal over its lifetime. A short collection of mechanical seal performance calculations has always been included in the earlier and current editions of the.

For the Reynolds equation to be satisfied one or more of the following statements must be true. Other system factors that affect seal leakage rates besides. A ro 0 b p 0 c h 0 d 0 e µ 4 For a to be true the seal geometry would cease to exist.

For an incompressible fluid k 1 where h1h2 the ratio of inlet to outlet face separation. No leakages at shaft. The mechanical seal Mechanical seals have the purpose of preventing leakage of a fluid liquid or gaseous through the clearance between a shaft and the fluid container.

Mechanical seals classified by Arrangement. Hello I am new learner for mechanical design of bolted tube-sheet and annular ring welded to shell. Mechanical seals can operate for many years without issue as long as theyve been properly selected for their application.

Fluid to be sealed. Objective to achieve with new design the mechanical seal. Detailed design calculations are not required in most cases where the application is a typical Plan 23 the mechanical seal contains a well designed circulating device best practices are used for the layout and piping of the loop and a well designed heat exchanger with known performance characteristics is used.

A precision machineis an integrated system that relies on the attributes of one component to augment the weaknesses of another component. Spring load seal surface A 01. We have integrated on-line propaganda with off-line propaganda to build brand name recognization.

PDF On Jan 1 2003 YGaft and others published Calculation and design of combined mechanical seal with self-adjusting clearance Find read. I am chemical engineer and know nothing about mechanical engineering design. Packing Division Europe 1.

Pressure of the fluid. The softer mechanical seal face usually has a smaller mating surface and is commonly called the wear nose of the mechanical seal. Here we emphasize the design of mechanical and structural.

Conditions such as temperature or pressure outside its design envelope can damage the seal and result in greater leakage rates. O-ring design performance can often determine overall equipment product success or failure and at worst cause catastrophic failure endangering both operators. A mechanical seal can now be defined as a device which prevents fluid leakage where a rotating shaft extends through a pressurized vessel.

Introduction Intoduction Parker PTFE seals and sealing solutions are used in the more traditional sealing markets like pneumatics and hy-draulics as well as in aerospace energy oil and gas the life sciences sector and in the field of renewable energies. Knowledge about heat exchanger theory calculations and design is important because of the widespread use of a variety of heat exchangers for industrial use and in everyday life. Application information Before design and material selections can be made at least the following conditions under which the seal will perform must be known.

Mechanical seal design calculations We commit ourselves to expand the influence of DMS Seals brand to enhance the enterprise reputation and overall competitiveness. In systems with highly corrosive fluids are recommended mechanical seals with external springs. The filter vessel is 813 mm OD with 14 mm thickness ID 785 mm carbon steel.

PTFE Seal Design Guide Parker Hannifin Corp. Can anyone help me with formula or calculation excel sheet for calculating the thickness. Industrial heat exchanger types include the most common double pipe heat exchangers shell and tube heat exchangers as well as spiral flat plate and fin tube heat exchangers.

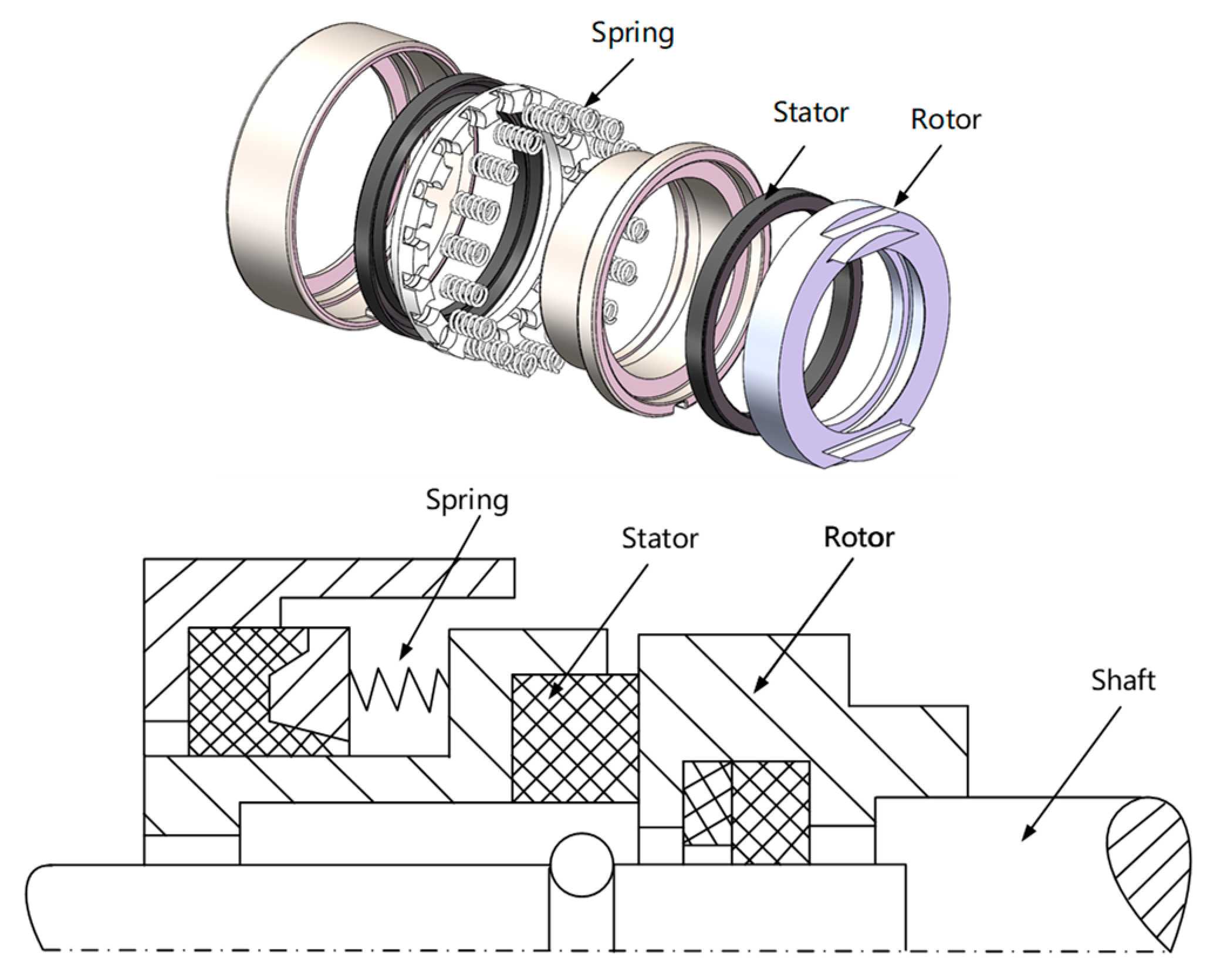

Targeted fabrication cost below RM 300000. Fig1 The main components of a mechanical seal are the seal rings on which a mechanical force is acting generated by springs or.

Calculate The Leakage Rate Of A Mechanical Seal Pumps Systems

Bushing Pv Calculations Daemar Inc

Fundamentals Of Mechanical Seals Seal Faqs

Calculate The Leakage Rate Of A Mechanical Seal Pumps Systems

An Introduction To The Five Key Features Of Good Mechanical Seal Design Reliability Matters

0 comments

Post a Comment